Perforated Metals

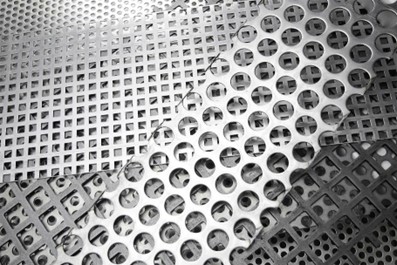

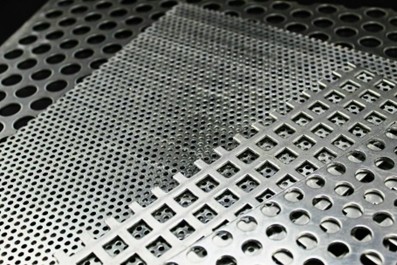

Perforated sheet metal is produced by punching a series of holes or patterns into a solid metal sheet. It offers a unique combination of strength, functionality, and design flexibility, making it ideal for industrial, architectural, and acoustic applications.

Perforated sheets are available in a wide variety of hole shapes, sizes, materials, and thicknesses, and can be customized to meet specific airflow, filtration, or visual requirements.

Key Features & Benefits

- Precision Patterns: Uniform hole sizes and placement for consistent performance

- Enhanced Ventilation: Allows airflow, light passage, and drainage while maintaining structural strength

- Acoustic & Aesthetic Use: Absorbs sound in architectural applications and adds visual appeal

- Durable & Adaptable: Available in multiple metals and finishes for indoor and outdoor use

Common Applications

- Architecture & Interior Design: Ceilings, partitions, sunshades, decorative panels

- Industrial: Machinery guards, filters, sieves, ventilation panels

- Automotive: Grilles, heat shields, ventilation covers

- Food Processing: Sieving, draining, and protective surfaces

- Agricultural & Mining: Screening, sorting, and drying operations

Material & Finish Options

- Stainless Steel: Corrosion-resistant for hygienic or harsh environments

- Galvanized Steel: Rust-resistant and cost-effective

- Aluminium: Light weight, corrosion-resistant, and easy to shape

- Mild Steel: Suitable for general indoor use

- Brass / Copper (on request): For decorative or electrical use

- Powder Coated / Anodized Finishes: For enhanced durability and visual customization

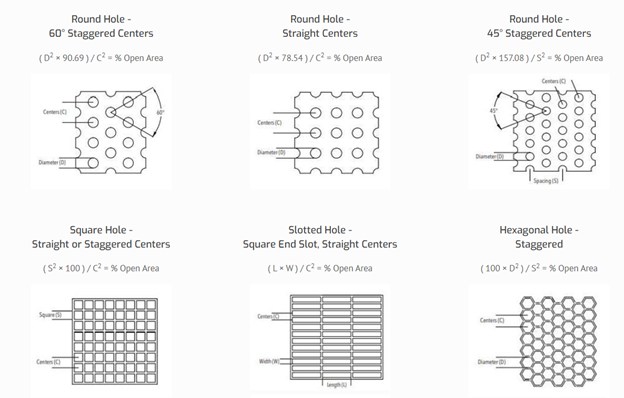

Hole Patterns Available

- Round Hole (Standard): Most common for general use

- Square Hole: Modern look, good for airflow and light transmission

- Slotted / Oblong: Allows directional ventilation or drainage

- Hexagonal (Honeycomb): High open area, great for strength and airflow

- Custom Designs: Logo shapes, decorative patterns, and branding available

Common Specifications

- Thickness: 0.5 mm to 5 mm (heavier gauges available)

- Sheet Sizes: Standard 4 ft x 8 ft, 1 m x 2 m, or custom sizes

- Open Area: From 5% to 70% depending on hole pattern

- Pitch (Spacing): Customizable based on performance needs

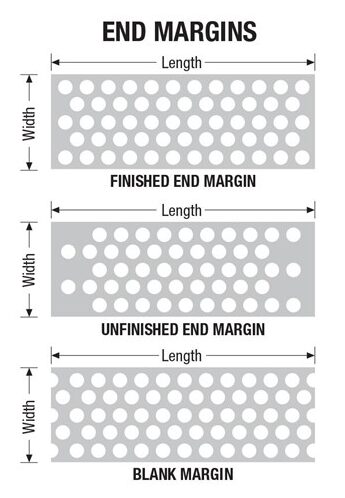

Customization Options

- Custom hole size, shape, and pitch

- Cut-to-size sheets

- Border margins or edge treatments

- Folding, forming, or bending for fabrication

- Custom finishes and packaging for large orders

Industries We Serve

- Architecture & Building Facades

- Manufacturing & Processing

- Agriculture & Food Industries

- HVAC & Acoustic Engineering

- Transportation & Automotive

- Energy & Utilities

Formula to determine the percentage of open area :